Category Archives: Uncategorized

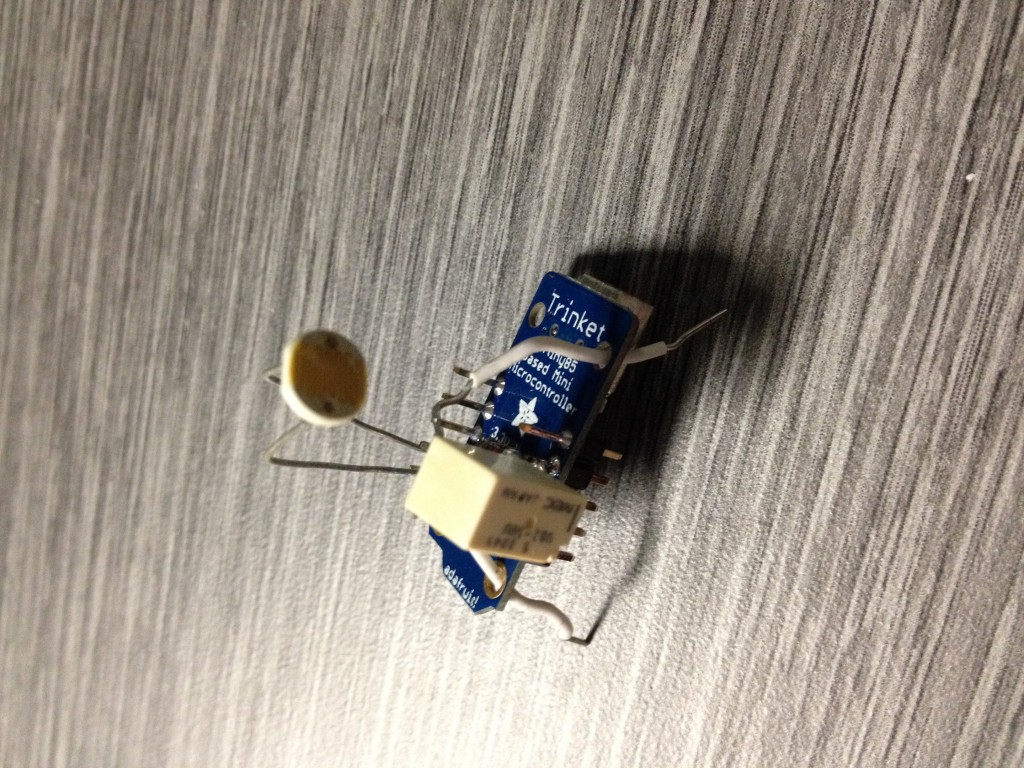

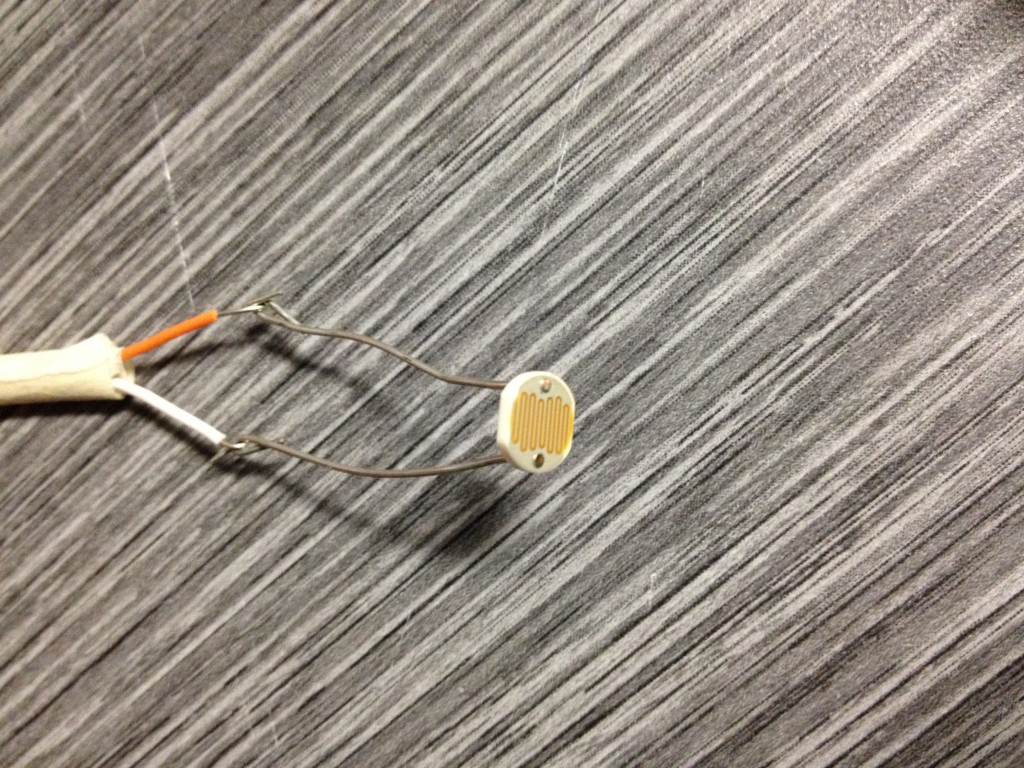

Lazer Tag Gun Light Control

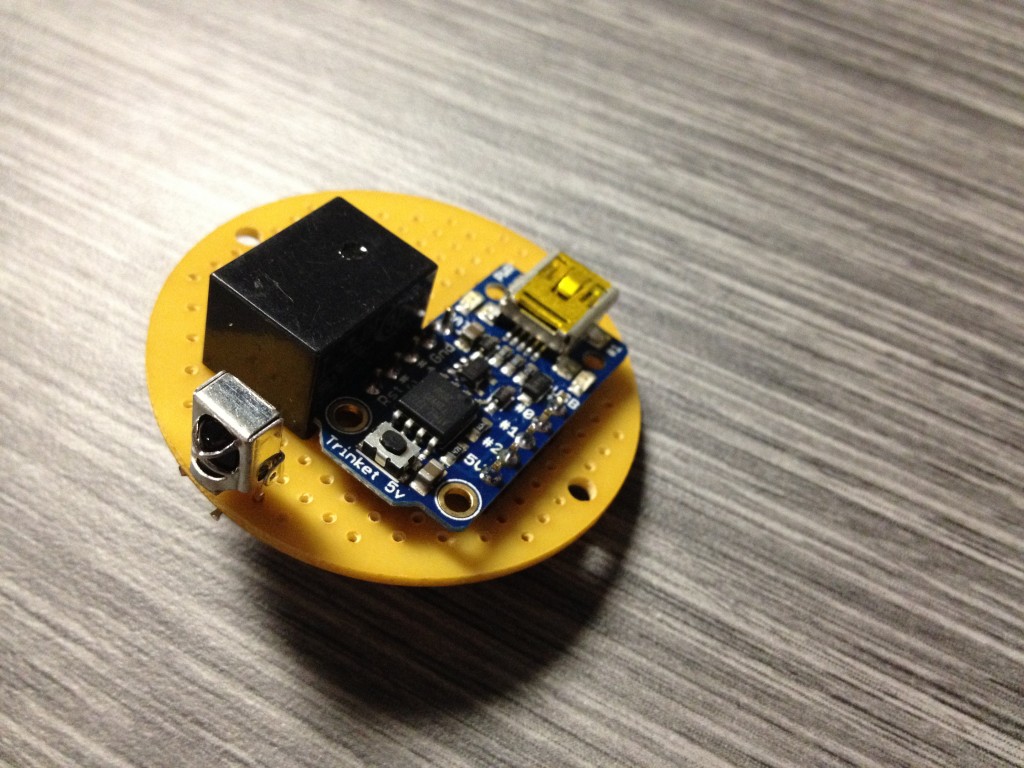

High Beam Controlled Garage Opener

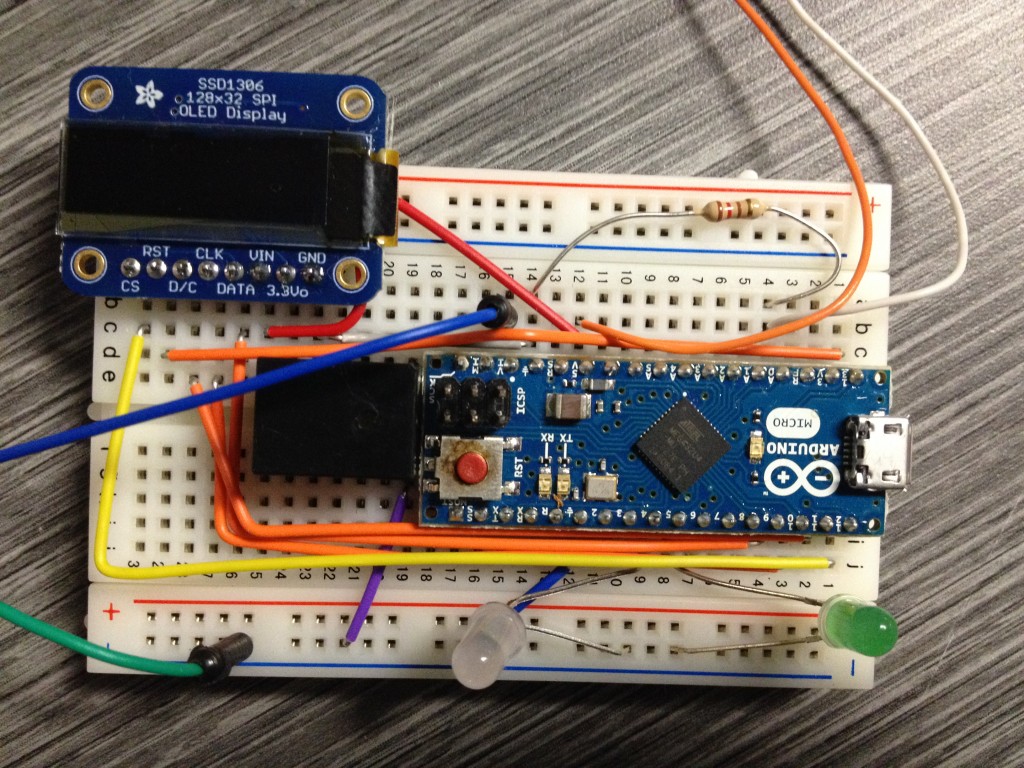

Quadcopter Elevation Control Tests

Lazer Tag Blows Stuff Up!

Furby teardown

Furby components:

2 capacitive sensing foil strips (head and around back and sides)

1 capacitive sensing wire ironed into front fur with connector

1 piezo element to right of mouth

1 microphone to left of mouth

1 or 2 LED lit monochrome LCD panels for eyes?

4 AA batteries

1 IR emitter/detector pair above eyes?

1 momentary switch in tail

1 geared motor driving

Protected: Private Post

Madden 06 Teaser Trailer

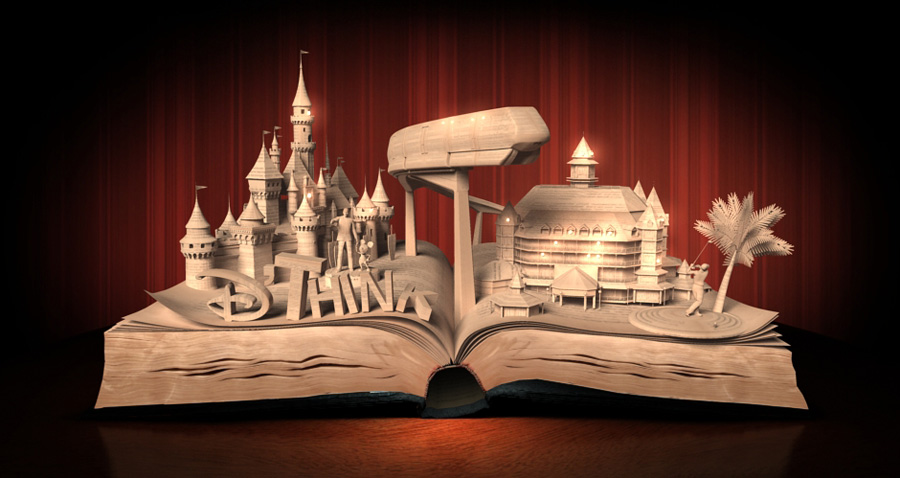

Disney Meetings Website

Since I was 5 I had always wanted to be a Disney animator. Life led me elsewhere career-wise, and I’m very happy for it, but this project came along as a freelance gig and I HAD to jump on it!

Since I was 5 I had always wanted to be a Disney animator. Life led me elsewhere career-wise, and I’m very happy for it, but this project came along as a freelance gig and I HAD to jump on it!

The site with all animations:

http://www.disneymeetings.com/

All of the modeling, texturing, lighting, animation, physics, rendering, and compositing was done by me. It was a one month job, and there were plenty of things I’d like to change, but the client (Disney) was happy with it and it had to be live by the deadline. So there it is.

Enjoy!

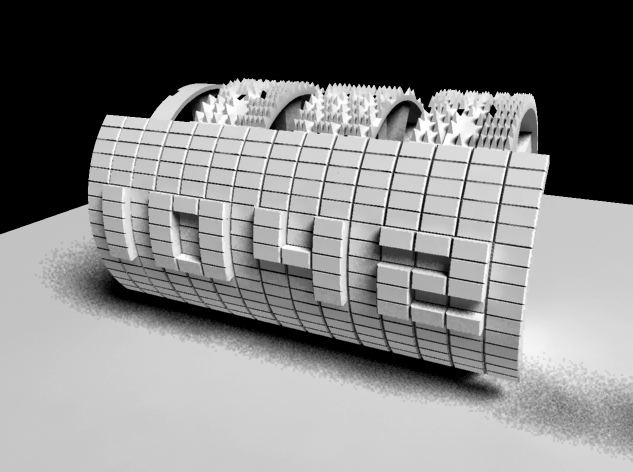

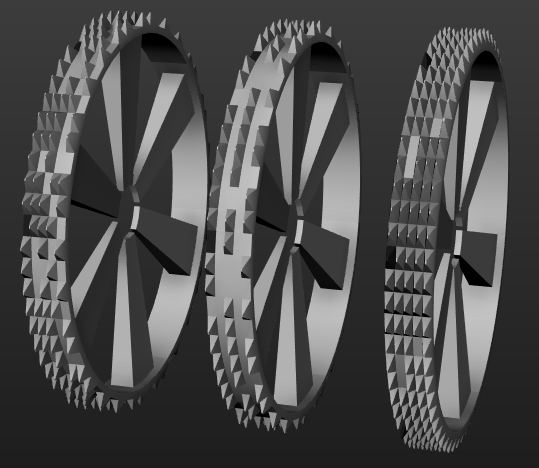

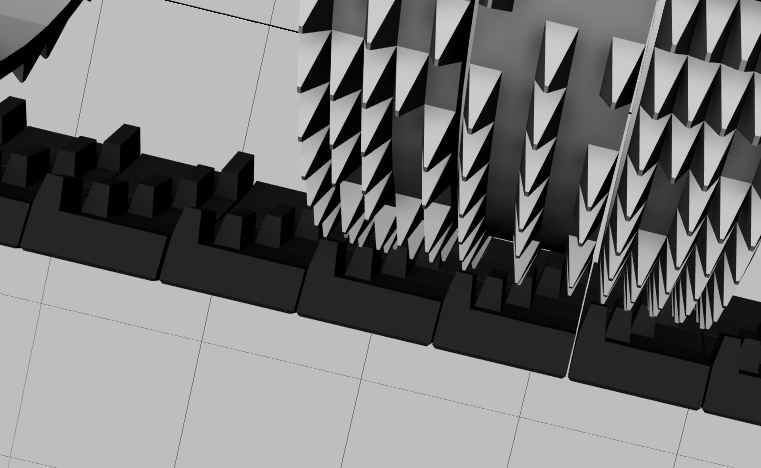

3D Printable Mechanical Digital Gear Clock

Mouthful of a title is it not?

This is an ongoing project of mine, which I intend to 3D print in the near future. It’s a segmented digital display, but driven mechanically. Each square segment has one tooth placed in a unique position, which allows the coded teeth of the circular gears to push it outward.

By pushing them out in the correct combinations (the part I’ve designed here), time numbers are constructed as physical blocks protruding from the surface of the display cylinder.